A Duracell battery, utilized in flashlights and remotes, doesn’t seem to be a high-tech candidate for a makeover. However one modder spent two weeks turning an strange battery right into a Bluetooth speaker that works and sounds nice.

Draining a battery to keep away from a chemical explosion isn’t glamorous, however it’s the beginning of this journey. The modder, Slivki Present, was anxious in regards to the alkaline innards in order that they constructed a short lived fan out of a toy automotive engine, blue electrical tape and a small propeller. This rickety system ran for 3 days, safely reducing the battery cost. Endurance like that’s spectacular particularly when in comparison with the choice: a hearth hazard on a workbench filled with instruments and goals. Solely after this gradual depletion might the actual work start.

Sale

Marshall Emberton II Moveable Bluetooth Speaker, Black & Brass

- SUPERIOR SIGNATURE SOUND: Delivers sound that’s wealthy, clear and loud, just like the artist supposed. Expertise absolute 360° sound with True…

- 30+ HOURS OF PORTABLE PLAYTIME: Affords 30+ hours of transportable playtime on a single cost. Its compact measurement, rugged sturdiness and dependable playtime…

- ROADWORTHY IP67-RATED DESIGN: Robust and resilient, boasting a particularly sturdy and easy-to-use design that options an IP67 dust- and…

Disassembling a battery casing appears easy, till you understand it was meant to final for years. The modder began with small drill bits and moved to bigger ones when the steel resisted. When that wasn’t sufficient, a rotary instrument with high-carbon metal bits was introduced in. To maintain steel shavings from making the workspace a glittering mess, they taped the batteries and used a rubber glove. Pliers had been used to extract the battery core, and the residual alkaline residue was scraped out with a picket popsicle stick. The hollowed shell was then cleaned with alcohol swabs.

The following hurdle was drilling 60 tiny holes right into a curved steel floor, a nightmare ready to occur – one slip and the undertaking is over. Early makes an attempt with a ruler produced variable outcomes so the modder opted for a extra refined answer: a 3D printed drilling template. This tradition jig had completely matched holes and stronger channels to maintain every drill bit on observe. The template was zip tied and scorching glued to the battery and when eliminated revealed rows of excellent holes, proof that preparation beats bodily drive.

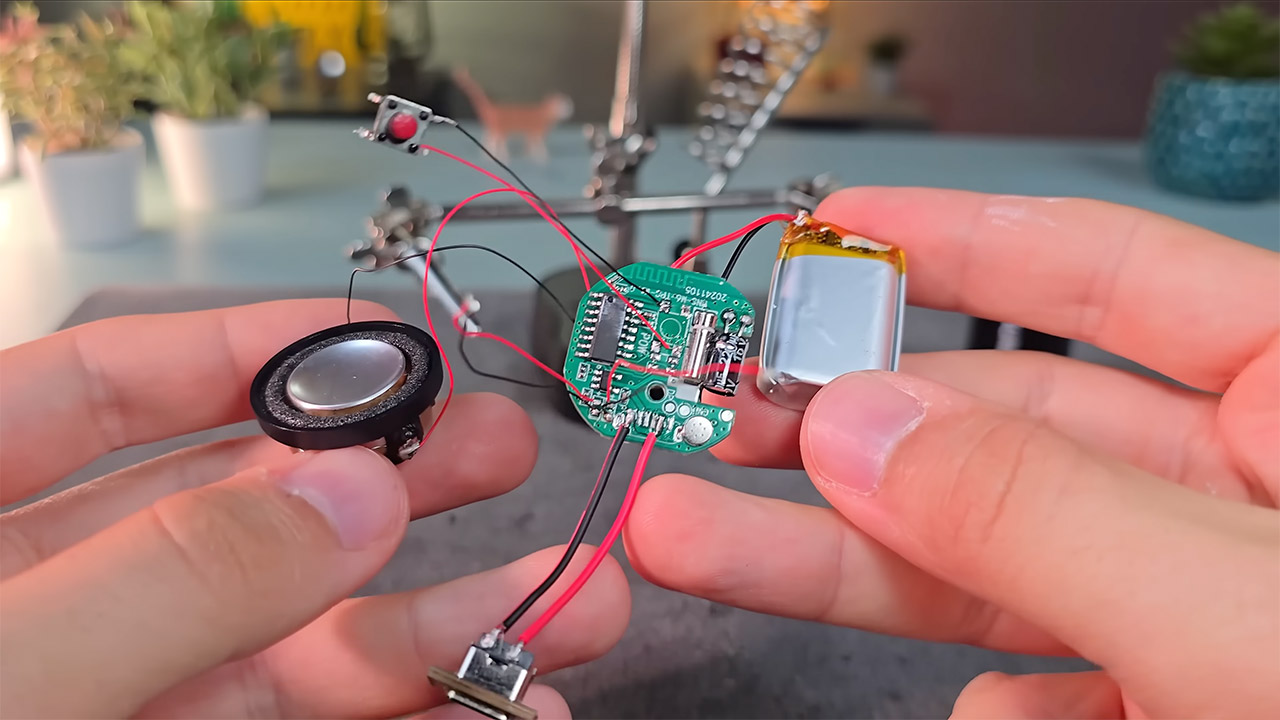

The electronics included a $6 Bluetooth circuit board, a small speaker, a battery, a push button and energy and charging LEDs. Easy in idea, however soldering 1mm LEDs with an enormous iron tip is a ache. The modder stated they couldn’t see the elements and labored principally by really feel relatively than sight. To place the button and charging port, a Photoshop design was printed on masking tape and used as a sticky drilling information.

Ending the undertaking required finesse, together with UV-curing adhesive like the type utilized in dental fillings which held the elements collectively with out gluing them in place; repairability was an enormous objective. A 3D printed sleeve held the speaker in place and improved sound contained in the steel case. The battery’s unique backside lid snapped again on and the high-tech secret was hidden.

[Source]