A $60 second-hand steel-frame bike, stripped to the bone and rebuilt with 3D printed PLA gears appears like a recipe for catastrophe. However YouTuber Effectively Completed Suggestions took this loopy thought and rode it – actually – at 20 km/h and proved that plastic can punch above its weight.

Effectively Completed Suggestions begins with a neighborhood market discover: a weathered steel-frame bike for pocket change. After a great wash to take away years of grime, the bike is torn down. Shifters, cables, rear derailleur, chain and entrance chainrings are eliminated, leaving a clean canvas. A particular cassette elimination software helps with the previous drivetrain, and the pedal meeting comes off with ease, because of the bike’s previous, however easy, one piece crank system.

FLASHFORGE AD5M 3D Printer Totally Auto Calibration Print with 1-Click on Max 600mm/s Pace, All-Steel CoreXY…

- Unleash Your Creativity: The Excellent Companion for Novices and Specialists Alike. The AD5M combines brand-new expertise and superior craftsmanship to…

- Obtain Excellent Prints with Ease: The AD5M is supplied with a totally automated one-click leveling system that exactly measures the nozzle-to-build…

- Core XY All-Steel Movement Construction: The AD5M includes a sturdy, revolutionary design that ensures high-speed printing with out compromising high quality. Its…

To help the customized drivetrain, Effectively Completed Suggestions constructs a base from a ten×40 mm metal flat bar present in a rubbish pile. An angle grinder is used to kind the bar so it matches across the bike’s kickstand mount and backside bracket. A 3 mm metal piece is offset and tack welded previous to everlasting welding. To counter flexing, a 30×10 mm rectangular metal tube is welded beneath the seat keep whereas rigorously navigating the rear wheel spokes.

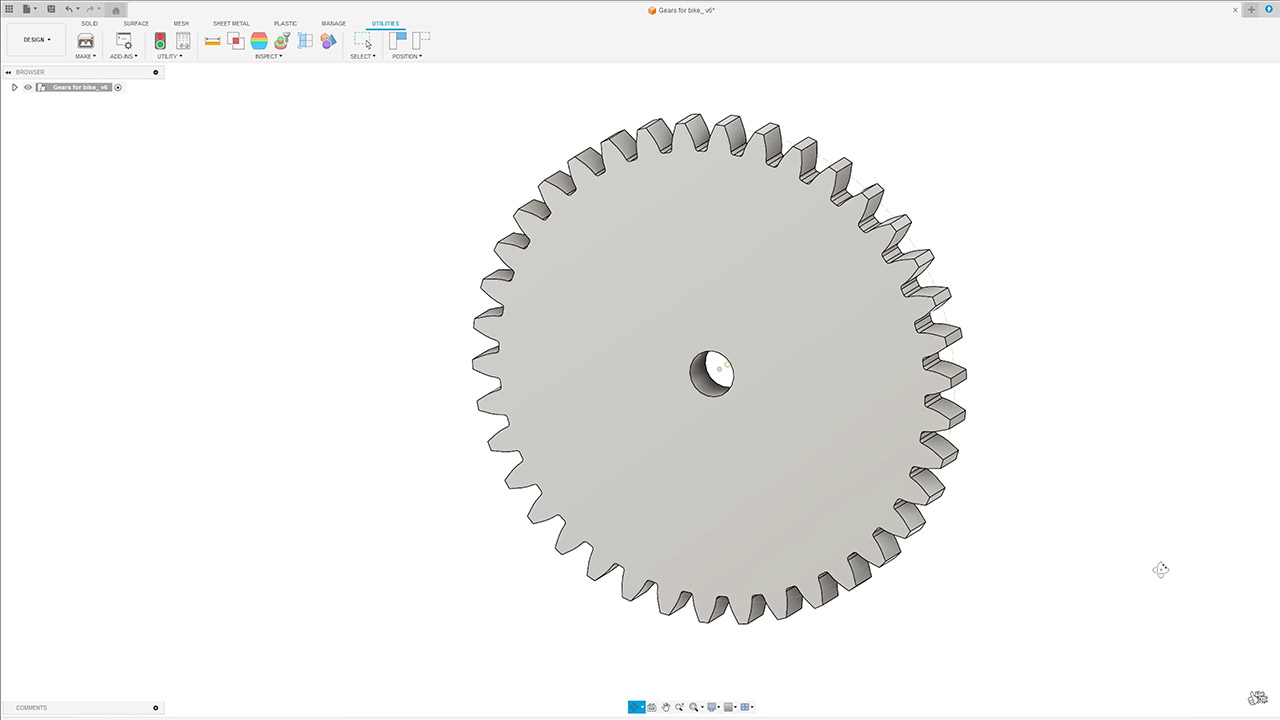

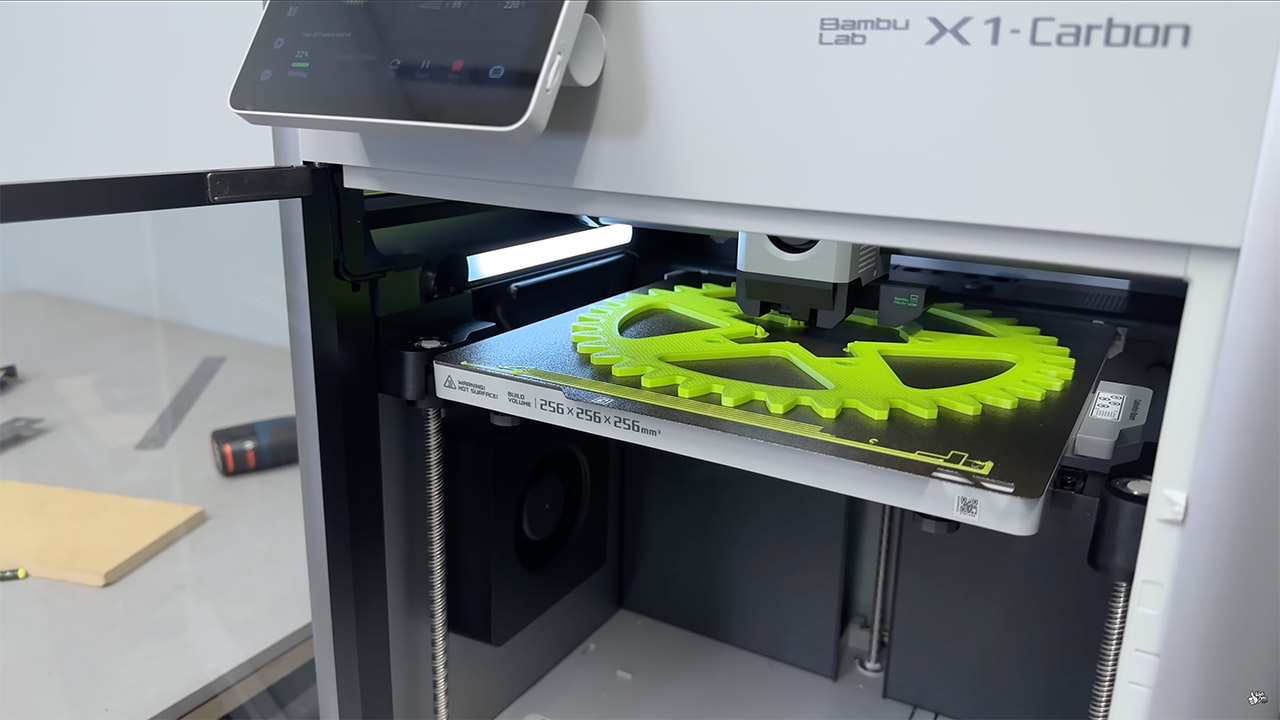

The gears had been created in Fusion 360 utilizing the spur gear add-in, and with only some parameters (tooth rely, gear thickness, and middle gap diameter), the software program produces excellent spur gears. The primary drive gear is a 38-tooth monster manufactured in PLA utilizing a Bambu Lab X1 Carbon printer. The scale is just restricted by the printer’s mattress. For the rear wheel, an 18 enamel gear is printed with 6 perimeters and 40% infill for energy, bolstered with a steel sprocket from the bike’s authentic cassette. Three 16-tooth loafer gears bridge the hole, permitting the pedals and again wheel to rotate concurrently.

The loafer gears include two 608 RS bearings (22×7 mm with an 8 mm internal gap) and have to be exactly positioned. Effectively Completed Suggestions reduces steel spacers to six mm for a decent match. They maintain the spacer utilizing an M8 Allen bolt and nuts, then use a marker to paint the bolt to point grinding progress. The bearings are hammered in with a hammer and socket, and so they spin easily with recent grease. To put the gears, one is left with just one bearing for improved visibility, and a 1 mm backlash is eyeballed to forestall binding. A drill press creates 7 mm holes perpendicular to the metal bar, tapped for M8 bolts, and secures the gears to the metal bar with chrome steel button head bolts for a clear end.

The uncovered steel is primed, and a customized blended paint is put to the body extension. This isn’t an ideal match, however after a number of clear coats and drying, it’s satisfactory. The ultimate meeting consists of reinstalling the again wheel, mounting the gears, and greasing the bearings. On the check trip, the bike simply reaches 20 km/h, and the PLA gears meet predictions of instantaneous failure. A squeak seems below robust pedaling, almost certainly as a consequence of dry gears grinding, whereas mild pedaling maintains every little thing easy and quiet.

[Source]